Whether fitting out a new practice, replacing a broken-down machine or simply upgrading, deciding on the best autoclave to buy should not be a rushed decision. As an expensive piece of equipment that plays a pivotal role in infection control, your autoclave should tick as many boxes as possible. Our Ultimate Guide to Autoclaves will arm you with everything you need to make an informed purchase.

What Is An Autoclave?

Autoclaves, also known as steam sterilisers, are self-sealing steel machines that use a combination of heat and time to kill these microorganisms and make the instruments safe to use again. Typically, an autoclave chamber is cylindrical as this shape more easily withstands high pressures than a box or cube.

Tabletop autoclaves commonly used in dental practices are roughly the size of a microwave and compact enough to not take up too much space. The autoclave machine was invented by Charles Chamberland in 1879 and the meaning of the name autoclave can be translated from Greek and Latin as a ‘self-locking’ device. Autoclaves are also used by other professions such as tattooists.

How do autoclaves work?

Autoclaves use steam to create a high-pressure environment at a temperature too high for microbial survival. This eliminates pathogens that may be resistant to soaps and detergents. The steam created in the autoclave allows for thorough sterilisation within dental instruments and tiny holes and crevices that could be missed during cleaning with detergent.

- The first stage of the autoclave sterilisation process is sometimes referred to as the “purge” phase. This is when steam created from heating water displaces the air within the autoclave chamber. Both temperature and pressure then begin to increase.

- The second stage is the sterilisation phase. During this phase, the exhaust remains closed causing the temperature and pressure to rapidly rise to the desired levels required to destroy bacteria, spores and other pathogens.

- The third phase is the exhaust phase. This is when pressure is released from the chamber, but temperatures remain high.

- The fourth and final stage is the cooling down phase. Once temperatures are low enough, the load can be removed from the chamber ready to be reused.

For help finding the right autoclave, speak to Michael our equipment specialist on 01634 877480.

Talk to our Expert

For help finding the right autoclave, speak to Michael our equipment specialist on 01634 877480.

Talk to our Expert

For help finding the right autoclave, speak to Michael our equipment specialist on 01634 877480.

N class autoclaves (generally not used in dental practices)

- Air removal happens by gravity displacement where the steam pushes the air out of the autoclave.

- Used for sterilising only simple materials, such as scalpels, and therefore not recommended for dental practices.

- Cannot be used to sterilise textiles, porous loads, hollow items or items in pouches as the cycles do not have the right characteristics to pass specific physical tests.

S class autoclaves.

S class autoclaves

- Remove the air inside the chamber using a steam wall which is denser than air. During the sterilisation cycle they perform this process three times to ensure that all the air inside the chamber is removed.

- Selective models of S class autoclaves come with a vacuum pump, but this is not a common feature.

- Essentially an intermediate class between N class and B class autoclaves and the characteristics are not defined by specific standards.

- Can be used to sterilise porous bagged products but not textiles, unless upgraded to B class.

- Usually has options for cycle programming, temperature selection and a drying mechanism to get the instruments dry.

B class autoclaves (Vacuum Sterilisers)

- The most suitable machine for a dental practices in accordance with European Standard 13060.

- Offer great flexibility and are suitable for a wide range of settings.

- Remove air from inside the chamber by means of a vacuum pump, creating a negative pressure that forces steam in.

- Can be used to sterilise all loads including solids, type A hollow instruments, type B hollow instruments, textiles, porous loads and wrapped instruments, both bagged and loose.

- Generally capable of much faster sterilisation and drying cycles, enabling dental staff to work much more efficiently.

Autoclave Testing

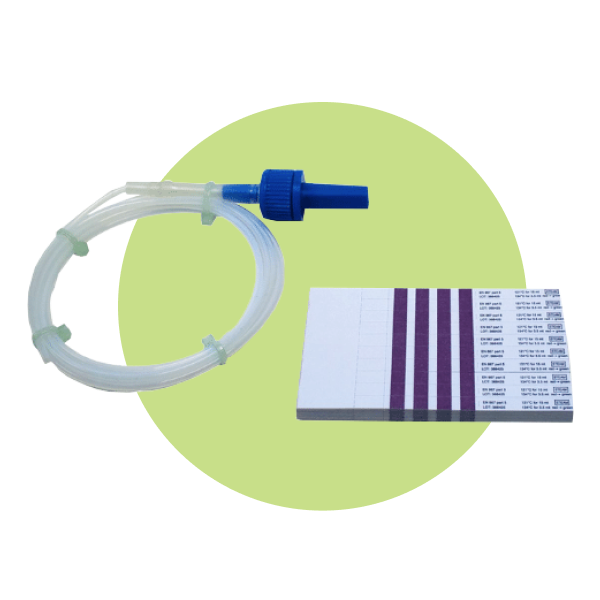

The effectiveness of sterilisation of any one cycle can be checked with the use of indicators or tape placed within the load. Colour changing sterilisation tape can be used in autoclaves to indicate necessary temperatures have been achieved and sterilisation has taken place.

Class B autoclaves require a steam penetration test once a day using either a Helix test device or Bowie and Dick.

The Helix test is aimed more at testing the effectiveness of air removal and steam penetration of hollow instruments and the Bowie Dick pack test is aimed more for testing the effectiveness of steam penetration on large porous loads. A printable data logger automatically records and prints out this test. It provides written confirmation of sterilisation times, temperature, and whether the autoclave passed the test successfully.

The other important test is the vacuum test. This is used is used to determine the air-tight integrity of a vacuum autoclave’s chamber and plumbing system.

Autoclave Validation

Sterilisation process validation is a procedure for obtaining, recording and interpreting the results required to establish that the process yields reliable, repeatable load sterilisation complying with predetermined specifications for sterility. Under healthcare standards and guidelines such as BS-ENISO:13060:2014, BS-ENISO:15883:1 and HTM 01-05, revalidation should be completed annually or in accordance with the manufacturer’s recommendations.

What To Consider When Purchasing An Autoclave

1. Capacity

Autoclave capacity, or chamber size, indicates how many instruments or pieces of equipment can be placed inside the chamber at any one time. B class autoclave capacity ranges between 8-22 litre. The larger the capacity the more expensive the autoclave and greater the energy consumption. The autoclave capacity required will depend on the requirements of an individual practice.

Some practices choose to use two smaller capacity autoclaves for faster cycle times and to allow two cycles to be carried out at once. Having two autoclaves is also practical should one break down.

2. Versatility

Not all B class autoclaves can deliver sterilisation cycles at the same speed. Some autoclaves offer shorter cycle time than others, but this generally will come at a greater initial cost. Some autoclaves offer gentle cycles ideal for sterilising sensitive items and porous loads.

It is important to ensure the autoclave has the appropriate choice of cycles to meet your sterilising requirements.

3. Price

As one of the more expensive pieces of smaller equipment your practice will need, it is always worth looking around for deals from trusted brands and manufacturers.

BA, one of the world’s leading manufacturers of autoclaves often has special offers on its Enbio sterilisers.

4. Traceability

One of the more recent advances in autoclave technology is the introduction of built-in USB functionality to record sterilisation cycles. Most B class and S class autoclaves now have label printers that can be connected to the steriliser for printing barcodes. This is designed for legal protection and as a way of improving your practice’s overall traceability system.

5. Repair, servicing and maintenance

The components and technology in autoclaves do fail from time to time, so it is beneficial to purchase from manufacturers who have a technical servicing department based in your country.

BA for example has a team of factory trained field-based engineers supporting dental autoclave repairs across the UK. To ensure the autoclave is working to maximum efficiency and reduce your chances of needing a repair, autoclave cleaners can be purchased for fast, effective and easy use.

Kent Express Recommends

BA Enbio Pro Autoclave

Along with being one of the world’s fastest B class autoclaves, the Enbio S comes with the following benefits:

- Sterilise up to 8 pouches per process

- 4 full cycles with drying per hour

- 6 times smaller and 3 times lighter than a typical vacuum autoclave

- Full drying means that pouches are bone dry. Not somewhat dry.

- In just 5 years, the number of dentists using Enbio autoclaves has grown to over 20,000 users worldwide.