Lithium disilicate is one of the four most common materials used to make dental crowns and other prosthesis along with solid metal, porcelain and zirconia. Holding clear advantages over alternative materials in certain areas, particularly aesthetics and speed, has made lithium disilicate the restoration of choice for many dentists, especially for anterior crowns or bridges.

What is Lithium Disilicate?

Lithium disilicate is a type of pressable, glass ceramic. It is used for the manufacturing of crowns and other dental prosthesis. First used in the early 1990s, lithium disilicate marked the arrival of the first lifelike, tooth coloured single dental crown unit in history. Its unique composition consists of many small and interlocking plate-like crystals that are structured to prevent cracks from growing. The material’s high glass content and filler particles are what gives it its aesthetic qualities and the ability to mimic the colour of natural enamel and dentine.

What Are the Biggest Advantages of Lithium Disilicate?

Aesthetics and speed are two of the main characteristics that give lithium disilicate an advantage over more traditional materials like metal and porcelain. Though metal is the gentlest material on opposing teeth and arguably the most durable, all-metal crowns have reduced in popularity in recent decades as the demand for natural looking restorations has grown. While metal-ceramic crowns have helped counteract this problem, the manufacturing of these crowns and other multi-layered crowns like porcelain is a lot longer a process compared to the pressable natural of lithium disilicate.

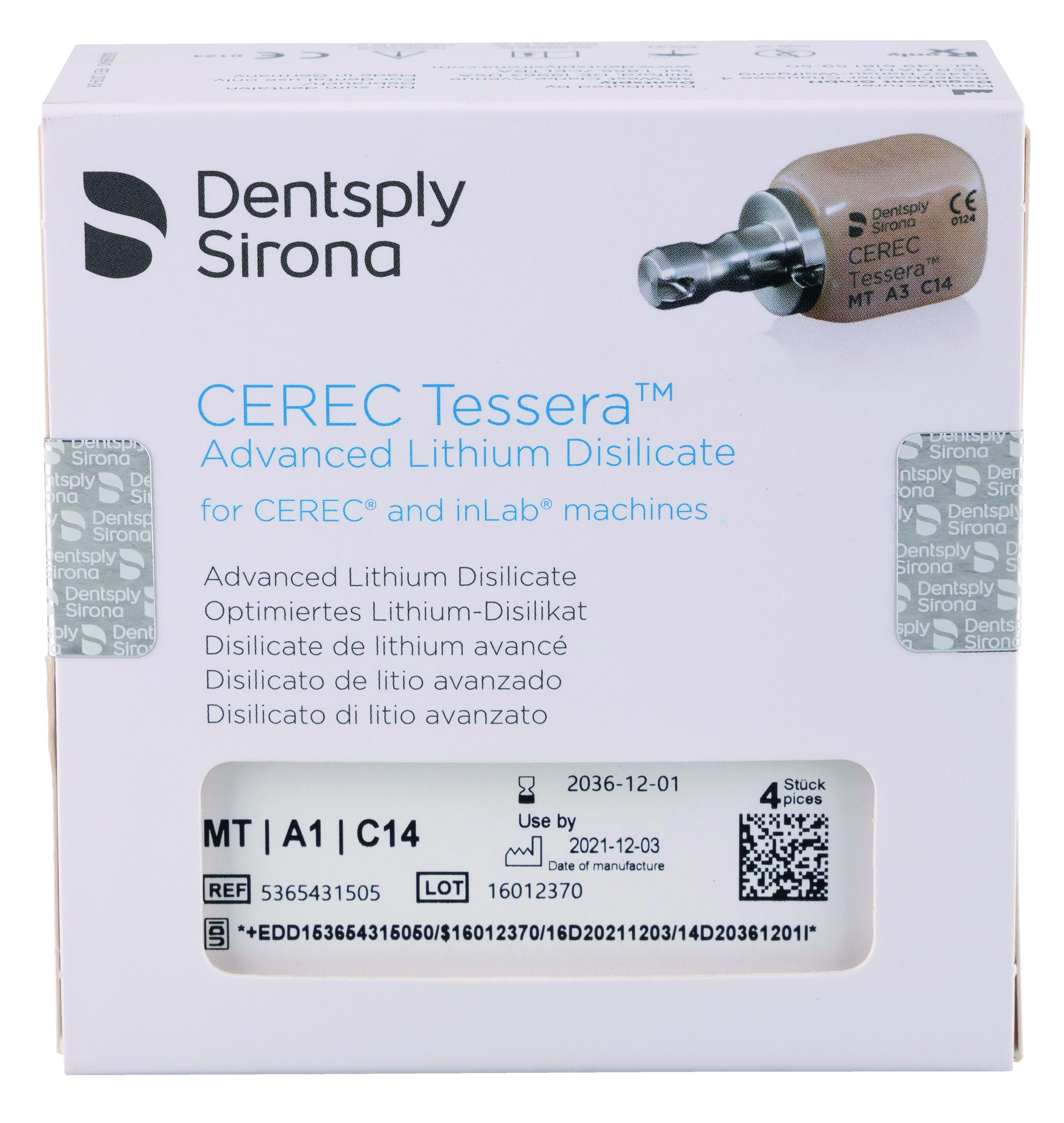

Lithium disilicate comes in CAD/CAM blocks that enable far quicker processing speed. Using a digitally taken impression, CAD/CAM blocks are placed into a milling machine and cut to shape to match the imported digital design. This process can take anywhere between 10 and 25 minutes depending on the size of the design and speed of the milling machine. The entire process of scanning, designing, milling and bonding to the tooth structure can all be carried out chairside and take under 90 minutes. These non-invasive, potentially single-visit procedures can help improve patient satisfaction and make a practice more productive and time efficient.

What is Advanced Lithium Disilicate?

Advanced lithium disilicate is the term used to describe CEREC Tessera, a glass ceramic that offers superior strength compared to traditional lithium disilicate. It has a unique chemistry that incorporates two complementary crystal structures within a glassy zirconia matrix. These two crystals work together to create an unrivalled fusion of strength. The composition uses virgilite crystals that are activated through the matrix firing process. This not only adds strength, but also contributes to the material’s tooth-like aesthetics.

How Else Can Cerec Tessera Improve Restorations?

The dual crystal structure of CEREC Tessera’s advanced lithium disilicate is designed to interact with the visible light spectrum for ideal translucence, fluorescence and opalescence. This helps it deliver the same tooth-like aesthetics as traditional glass ceramics even for the most highly visible aesthetic restorations. The blocks are designed to simplify shade selection with a range of true shades available that match the final restoration without the need for any specialised selection tools.

Using CEREC Tessera blocks can be a quicker process compared to other glass ceramics as the material is delivered already partially crystallised to allow for fast and accurate shade selection. Clinicians can save up to 44% of total processing time (grinding and firing), according to Dentsply.

How much does CEREC Tessera cost?

CEREC Tessera Starter Kit

How much does CEREC Tessera cost?

A simple definition of CAD/CAM dentistry is the use of digital software to design and manufacture dental restorations and prostheses. CAD stands for computer-aided design and CAM stands for computer-aided manufacturing. The technology can be used to create crowns, dentures, inlays, onlays, bridges and veneers among other things. The speed of the CAD/CAM process allows for dental prosthetics to be designed, manufactured and delivered to the patient in quick time, sometimes the same day. The wider system of using computer assisted technologies to produce restorations is known as CEREC (Chairside Economical Restoration of Aesthetic Ceramics).