Dental handpieces are often stereotyped as ‘problematic’ and ‘high maintenance’ by some in the dental profession. These misconceptions are in large part born out of a lack of understanding around handpiece maintenance best practice.

As one of the fastest moving objects on the planet capable of reaching speeds of up to 450,000 revolutions per minute (rpm), high speed handpieces naturally do require some TLC to maintain durability and peak efficiency. Cleaning your handpiece properly and picking the right brand/manufacturer to begin with can help your handpieces stay good for several years and reduce the amount spend on repairs.

What Is Inside A High Speed Handpiece?

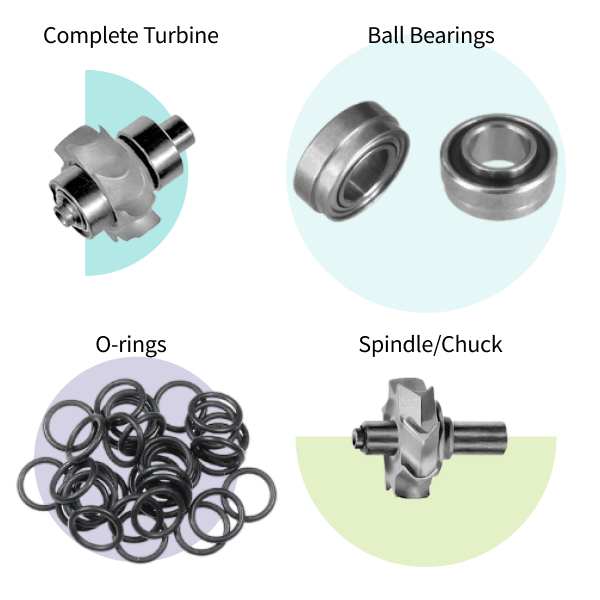

It is worth understanding the basics of what is going on inside a high speed dental handpiece for a better idea of what parts you are cleaning and why. Inside a high speed (air driven) handpiece is a turbine, two bearings and two O-rings. Air pressure from the turbine is what drives the rotational motion of the attached dental bur for cutting or polishing.

The O-rings are what provide vibration dampening and noise dampening. They also give the bur some flexibility of movement. Ball-bearings are a critical component of any handpiece and are what normally breaks and cause it to stop working properly. The lubricated ball-bearings hold a friction-grip burr firmly and centrally, allowing the shank of the burr to rotate smoothly along a central axis with minimal friction. Any debris that gets into the bearings can wear away at both the races that contain the balls and the balls themselves. This will cause the rotation to get sloppier and negatively affect performance.

Signs that this might be occurring inside a handpiece include noisier operation and more vibration. The bur might also start jumping around. Regular cleaning and lubrication are essential to helping the bearings last longer and ultimately prolonging the life of the handpiece.

How To Properly Maintain Your High Speed Handpiece

A handpiece should be lubricated prior to autoclaving every time without fail.This process involves spraying oil inside the handpiece to lubricate the bearings. Any excess oil should then be run out the end of the handpiece.

It is only necessary to lubricate the smaller of the two large holes on the handpiece. This is the hole which air is driven into. To ensure the bearings are fully saturated with oil, it is advisable to spray until oil drips out of the head. Running out the excess oil is essential otherwise the oil can bake in the autoclave and turn into a gluey substance that makes the bearings sluggish.

Further maintenance tips on spraying techniques, cleaning the external surface and lubricating the chuck can be found at the link below.

Choosing The Right Handpiece

Choosing a reliable handpiece brand can give your handpiece the best chance of a long life. Ensure you always buy your handpieces from a reputable dental supplier such as Kent Express. Do not be tempted to buy cheap copies online, for example from well-known auction websites – you have no idea where the product is manufactured, quality is often an issue, and cheap copy handpieces often do not meet European safety standards.

Ensure your handpiece holds the CE mark and look for manufacturer guarantees. Ensure the manufacturer can offer technical support post-purchase if required.

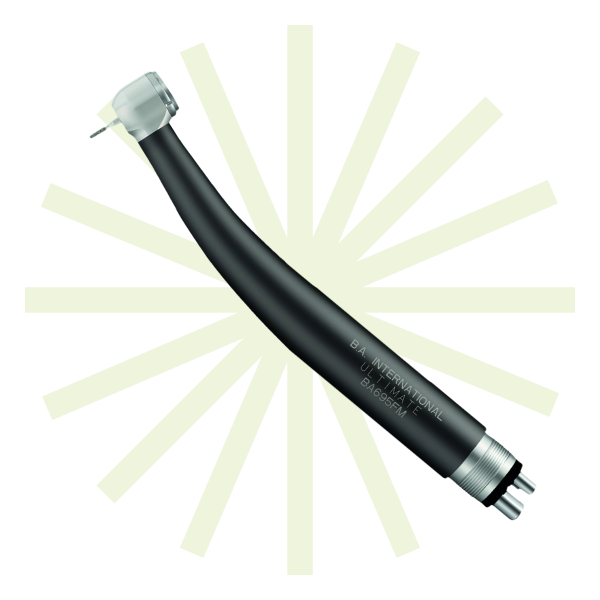

The country of manufacture is also important: Germany and Japan are known to produce excellent quality handpieces. This is where most BA International handpieces are manufactured.

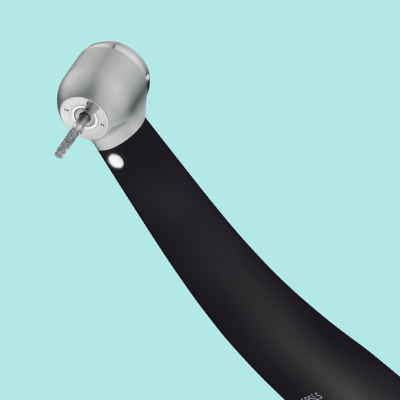

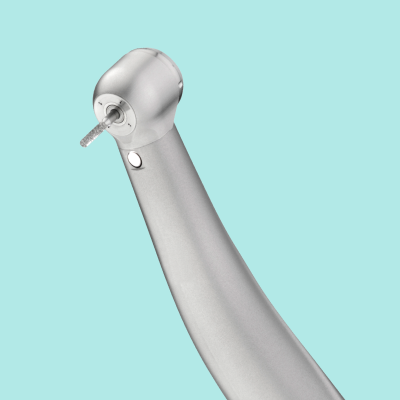

Why Choose BA High Speed Handpieces

All high-speed handpieces in the BA International Ultimate range are suitable for washer disinfectors and autoclaves for easier and quicker sterilisation. BA Ultimate handpieces also be manually cleaned and lubricated in accordance with manufacturer guidelines.

When a professional repair is needed, BA International can offer the longest serving expertise and experience in the dental handpiece repair field and a free postage paid repair pack that can be used to safely send handpieces off in.

It is no secret that dental handpieces are not cheap. To help your practice budget, Kent Express regularly offers reduced prices and free stock deals on BA handpieces.

Our handpiece specialist Jack is also available to answer any questions on our handpiece range and can be contacted directly on 01634 878759.

For additional help finding the right dental handpiece, motor, coupling or maintenance kit, speak to Jack our handpiece specialist on 01634 878759.

Find the right handpiece

For additional help finding the right dental handpiece, motor, coupling or maintenance kit, speak to Jack our handpiece specialist on 01634 878759.

Find the right handpiece

For additional help finding the right dental handpiece, motor, coupling or maintenance kit, speak to Jack our handpiece specialist on 01634 878759.