Why is Handpiece Maintenance So Important?

Dental handpieces are one of the most important and costly pieces of equipment used regularly in the dental practice. Correct handpiece operation and maintenance are just as important as the original investment. Looking after equipment properly can benefit dentist, practice, and patient. Regular maintenance of dental handpieces using the correct products and equipment can help extend their life, ensure that they are performing correctly and help save money in the long run as regular attention should minimise the chance of handpieces malfunctioning. Handpiece maintenance is not straightforward. Thinking carefully about how to approach the task and considering what cleaning processes could be made easier can help ensure your handpieces perform at their best.

Following Manufacturer Guidelines

There are a huge variety of handpiece ranges on the market, with unique functionality, features and internal components. It’s important to follow the specifications outlined in the manufacturer’s instructions when it comes to both operation and maintenance. Air pressure is one area where professionals can go wrong. Higher air pressure isn’t synonymous with better performance and can cause damage even at low speeds. Refer to the manufacturer guide to determine ideal pressure levels. Only manufacturer recommended products should be used during handpiece maintenance, as using others may void any warranty and potentially result in an expensive replacement should they cause damage or compromise the life of the handpiece.

General Tips

Handpiece lubrication is an important area to consider in detail. It's generally recommended to lubricate handpieces before sterilisation – a good quality lubricant will not break down during the sterilisation process. However, it is important to not over lubricate handpieces as this can lead to them becoming clogged and impact performance. Always use a lubricant that includes cleaning properties to keep mechanisms in good working order – these can also save considerable time. It is also sensible to use a handpiece lubrication device to ensure consistent handpiece lubrication.

Dental handpiece lubrication machines

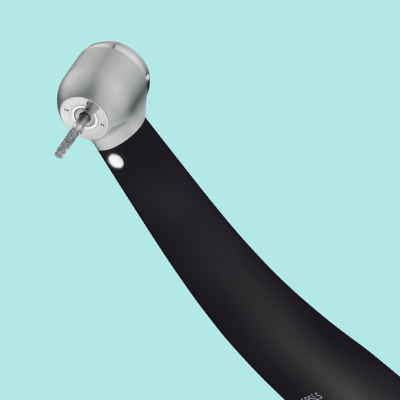

Assistina TWIN MB-302

Dental handpiece lubrication machines

With so many aspects to consider, it’s easy to see how handpiece maintenance can fast become a time-consuming task. Automatic maintenance systems are designed to ease this burden. The cutting-edge Assistina TWIN automatic handpiece maintenance device from W&H provides an exceptional, consistent standard of lubrication in just 10 seconds.

Using a combination of pressurised air and unique oil nebulisation technology, the Assistina TWIN cleans and lubricates the internal mechanism simultaneously. It also boasts a time-saving dual chamber system and an array of different adaptors, meaning that you can process up to 360 handpieces per hour, ensuring that they are always ready when you need them.

Investing in an automatic lubrication device, can also provide the following advantages:

- Less staff time involved

- Consistent lubrication (less room for human error)

- Measured oil and air flow settings