The complete procedure for the securing of an indirect restoration to tooth structure can sometimes be long and complex. Several considerations must be made, such as which indirect restorative material is best for that particular indication and does the tooth in question have the appropriate support for the prosthesis? Does the support for the restoration have specific impression material considerations? What material should we consider for the temporary? How will we secure it to the prep? This guide aims to address and provide solutions to some of these questions.

Preparation

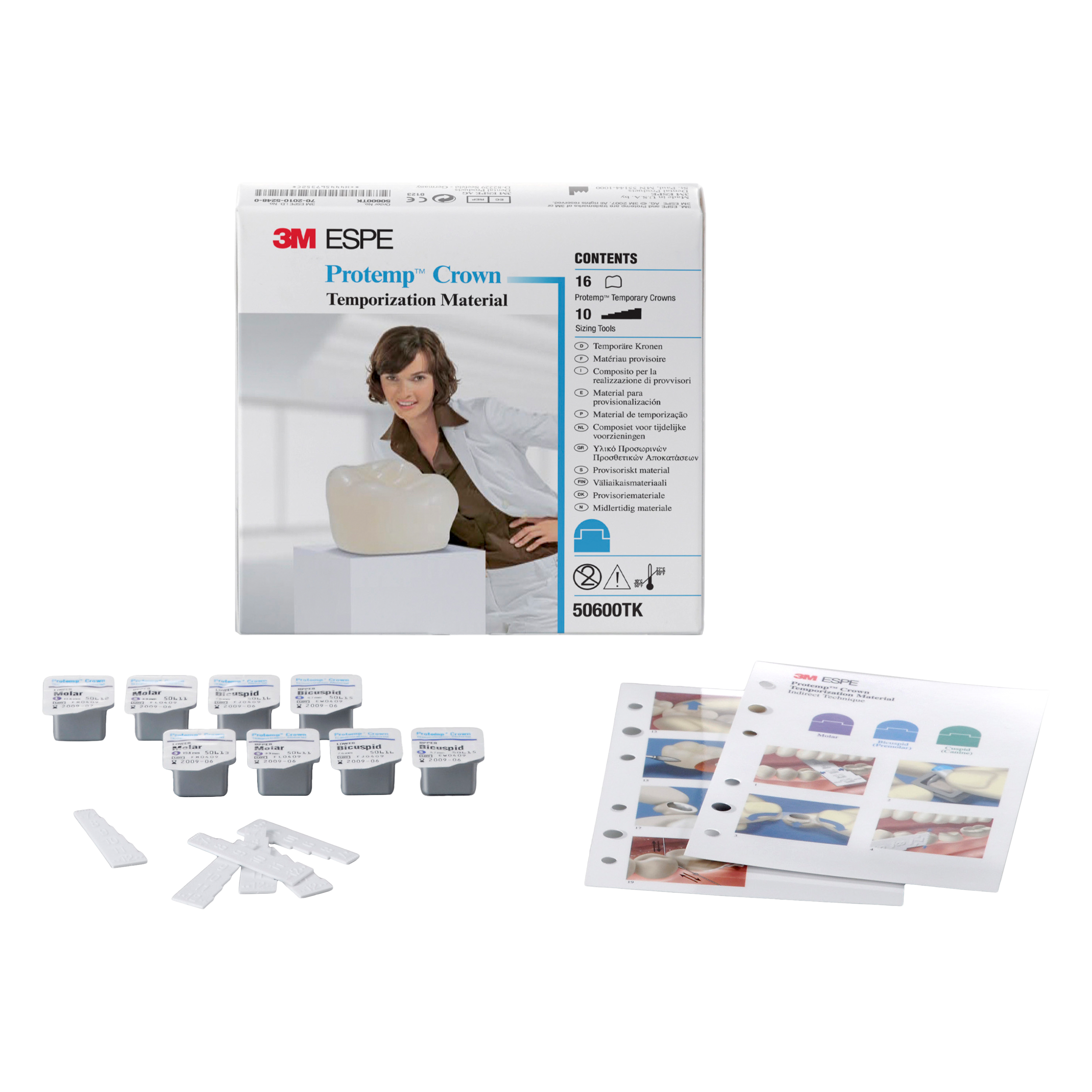

Temporary material selection needs to be based on the clinical situation.

3M Protemp 4 Temporisation Material

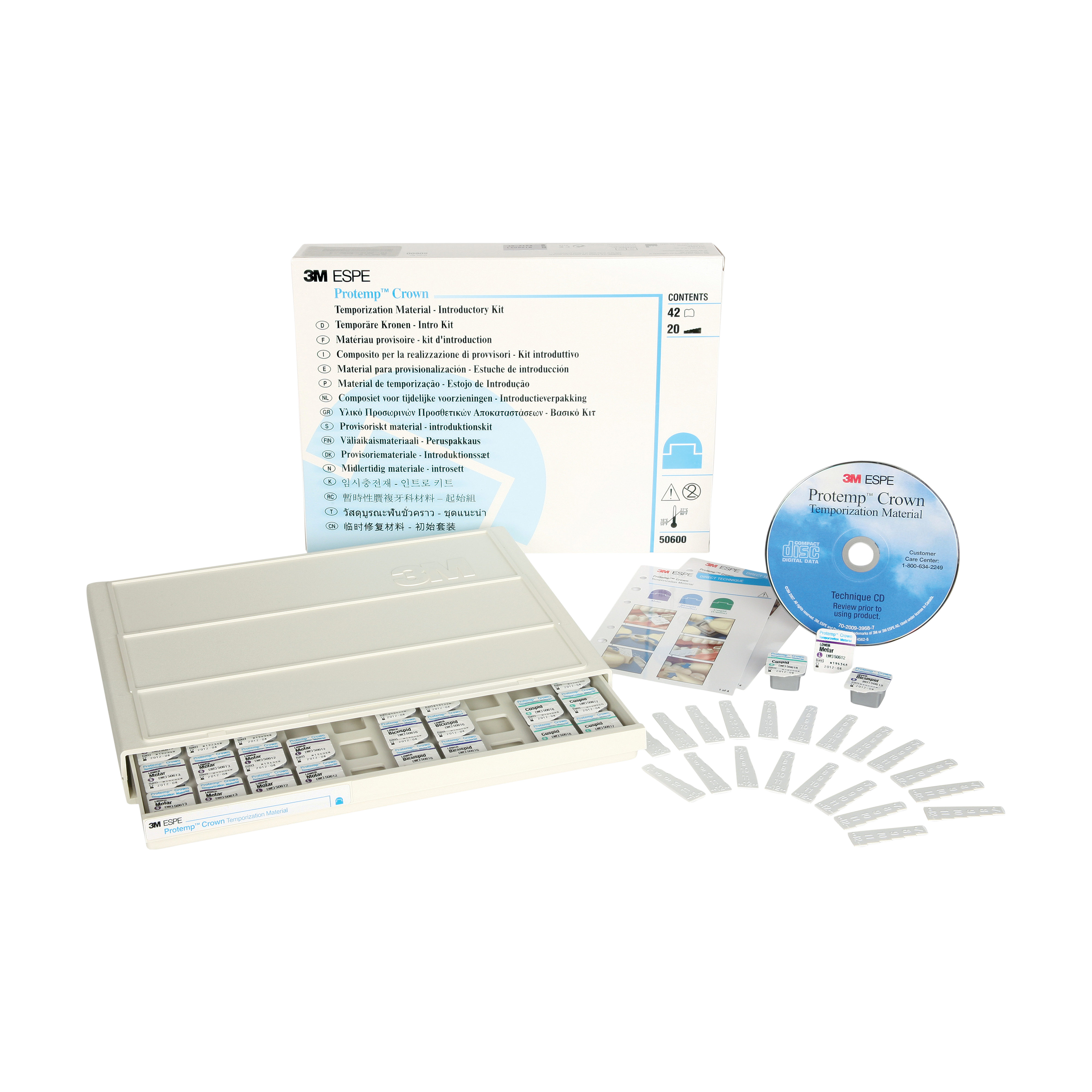

Protemp 4 Temporisation Material Intro Kit A2 50ml

3M Protemp 4 Temporisation Material

3M Protemp 4 Temporisation Material is the only 100% nano filled temporisation material currently on the market. The nanofiller provides high strength and excellent aesthetics and allows good adaptation to the soft tissues. Indicated for 12 months, this gives plenty of time for perio or other treatments to aid the development of healthy soft tissue which will aid the overall final aesthetic appearance of the final restoration.

Temporary materials provide the appropriate prep protection, functionality for the wearer and adequate aesthetics while the final restoration is being customised. Prior to temporisation, final impressions will have been taken to enable the laboratory to produce the appropriate indirect restoration. This typically takes a couple of weeks, so it is important that the chosen temporisation material is indicated to last for at least this length of time.

Protemp 4 Temporisation Material Intro Kit A2 50ml

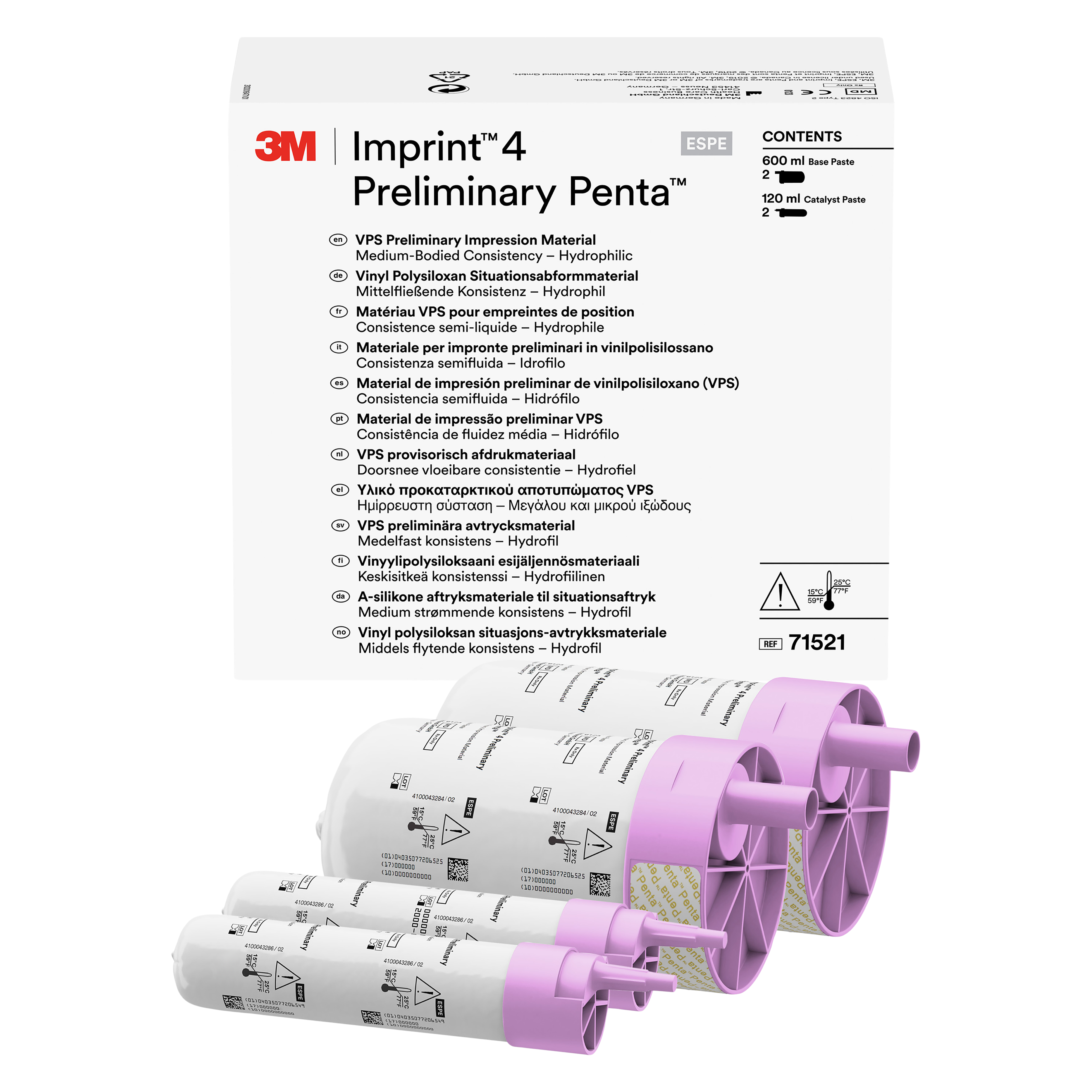

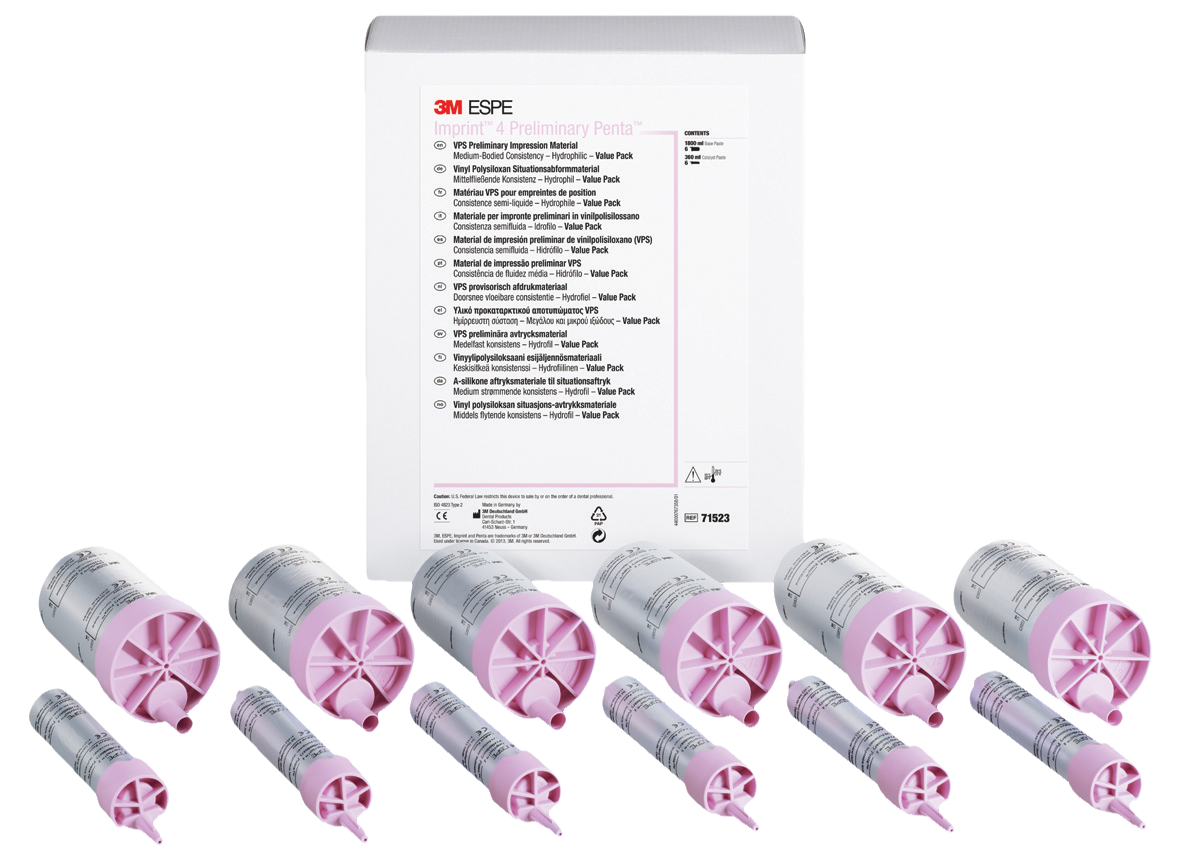

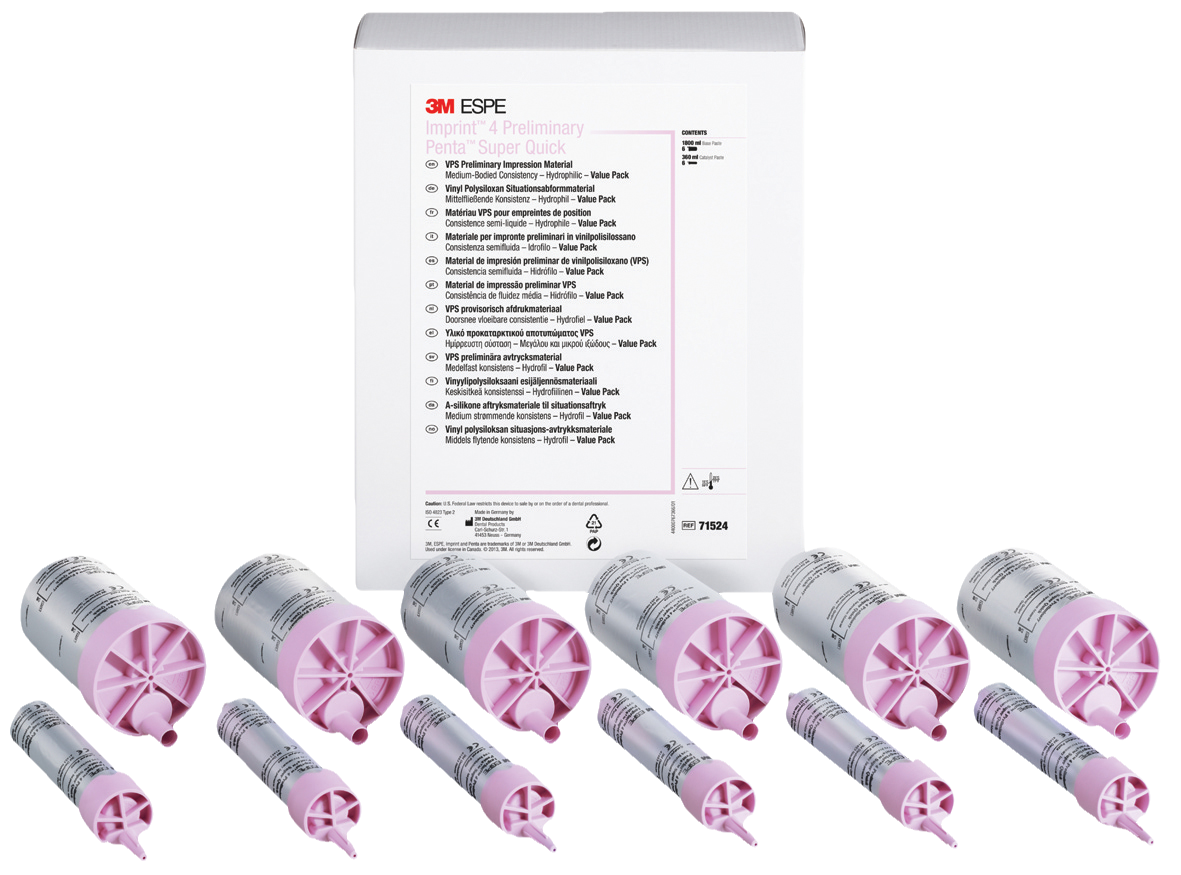

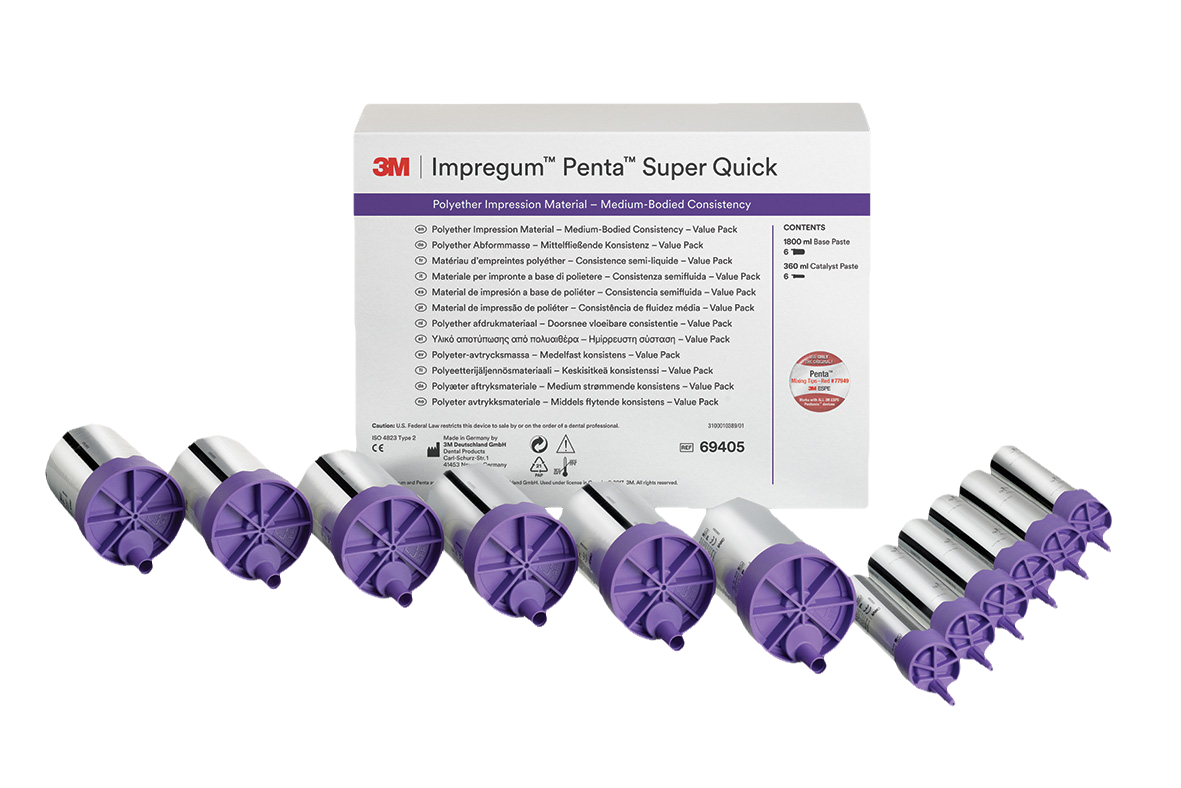

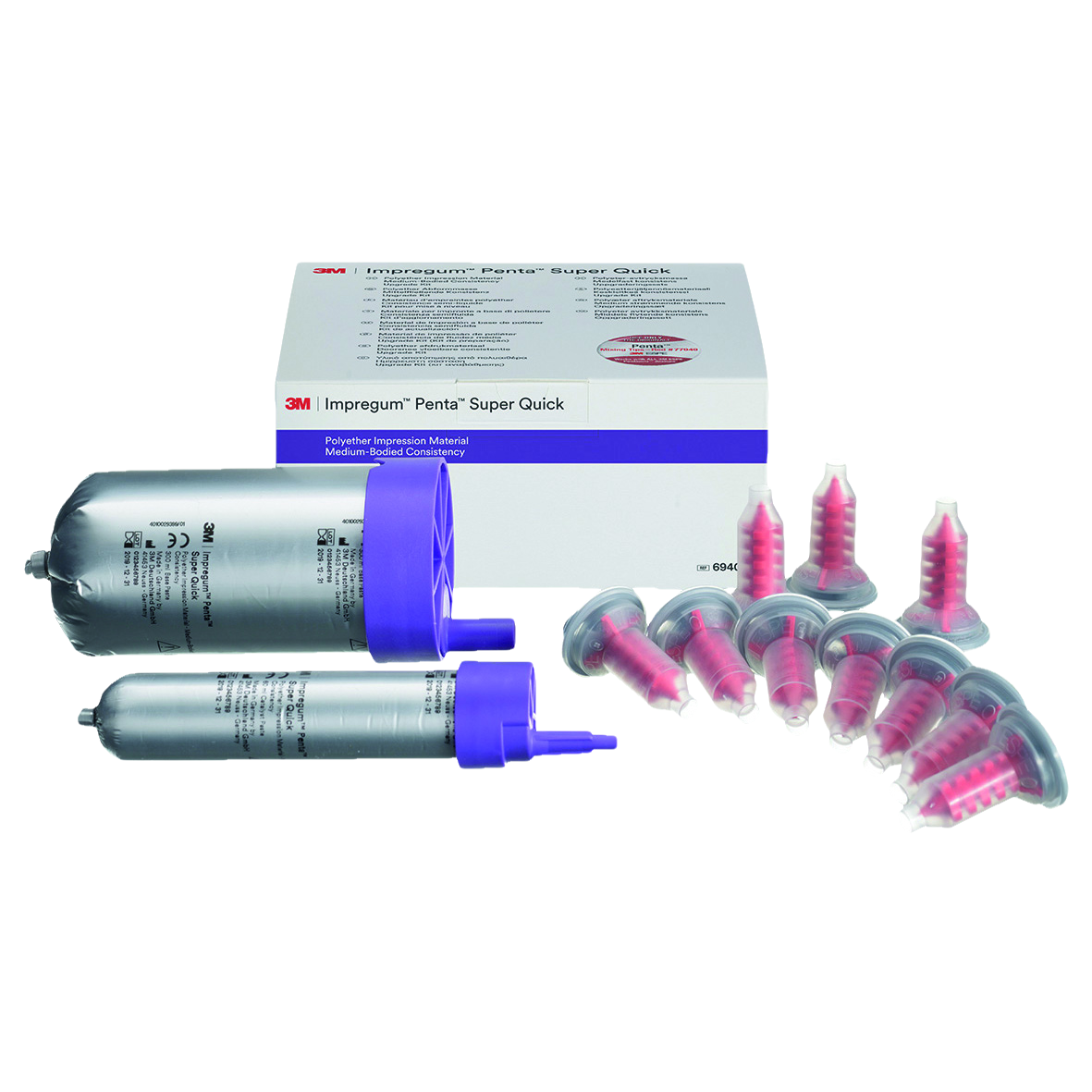

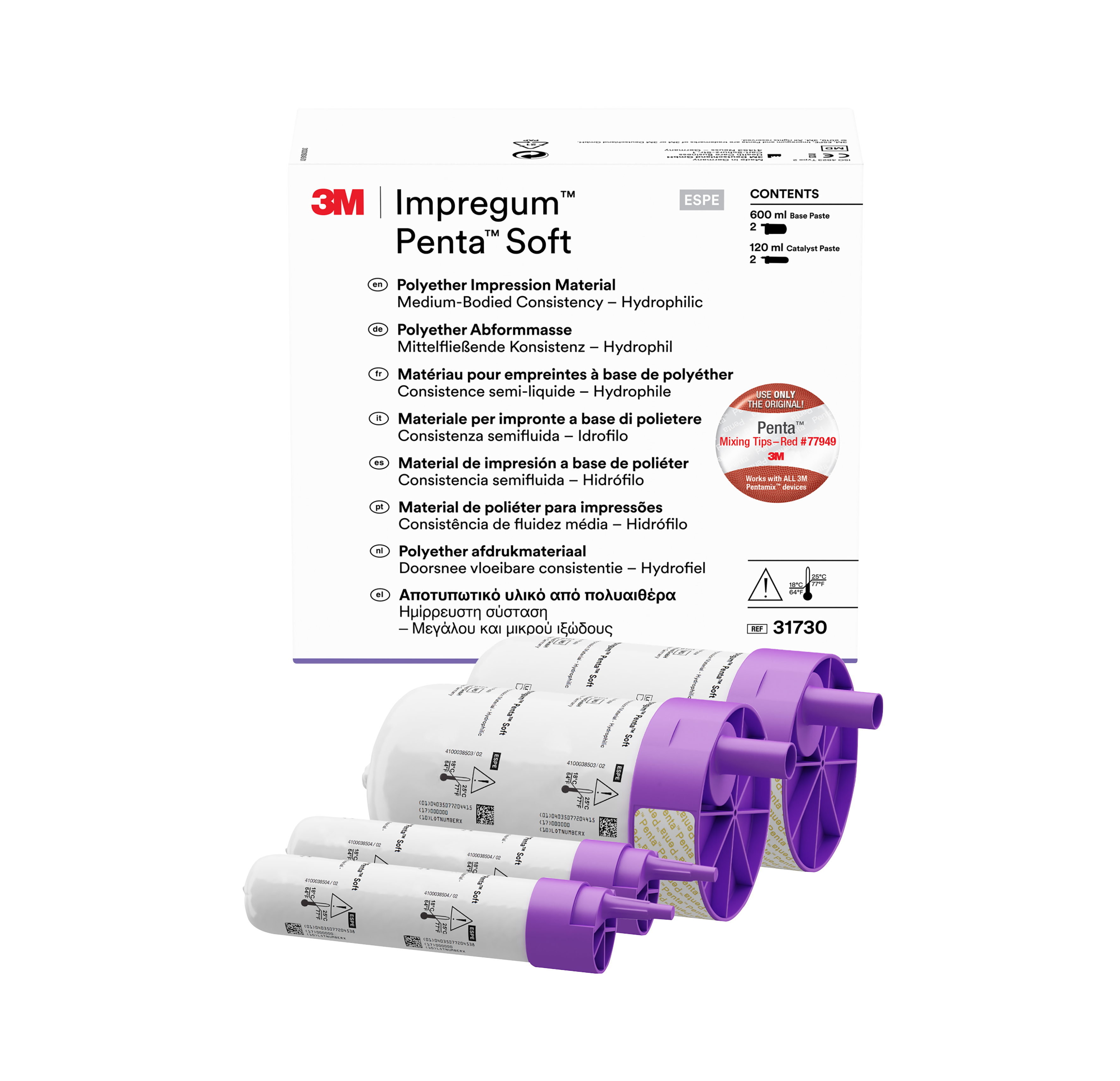

Impression Materials

Impressioning is key to getting an accurate fitting restoration and the overall aesthetics of the final prosthesis. For accurate impressions we typically have two material types to choose from; A-Silicone (often referred to as VPS materials) or polyether. Whichever you choose, the key is to ensure that the material used is hydrophilic. By their difference in chemistry, polyether impression materials are one of the few naturally hydrophilic impression materials on the market. A-Silicones are made to be hydrophilic by the addition of surfactants, but these often take a while to rise to the surface of the materials meaning that on contact in the oral cavity, many A-Silicones often remain hydrophobic for several seconds before the surfactants reach the surface.

Now the oral cavity is not dry. Dentine is not dry. Most dental procedures involve water and may have resulted in some bleeding or the production of other fluids. So, it is critically important that the impression material of choice can cope with some degree of moisture and adapt nicely to the prep in question. 3M Imprint 4 VPS Impression Material is one of the most hydrophilic A-silicone materials on the market due to its novel chemistry. It is also the only A-silicone currently to offer active self-warming, a process whereby the material warms during its working time to approximately 37°C resulting in a snap-set setting profile right at the end of the working time.

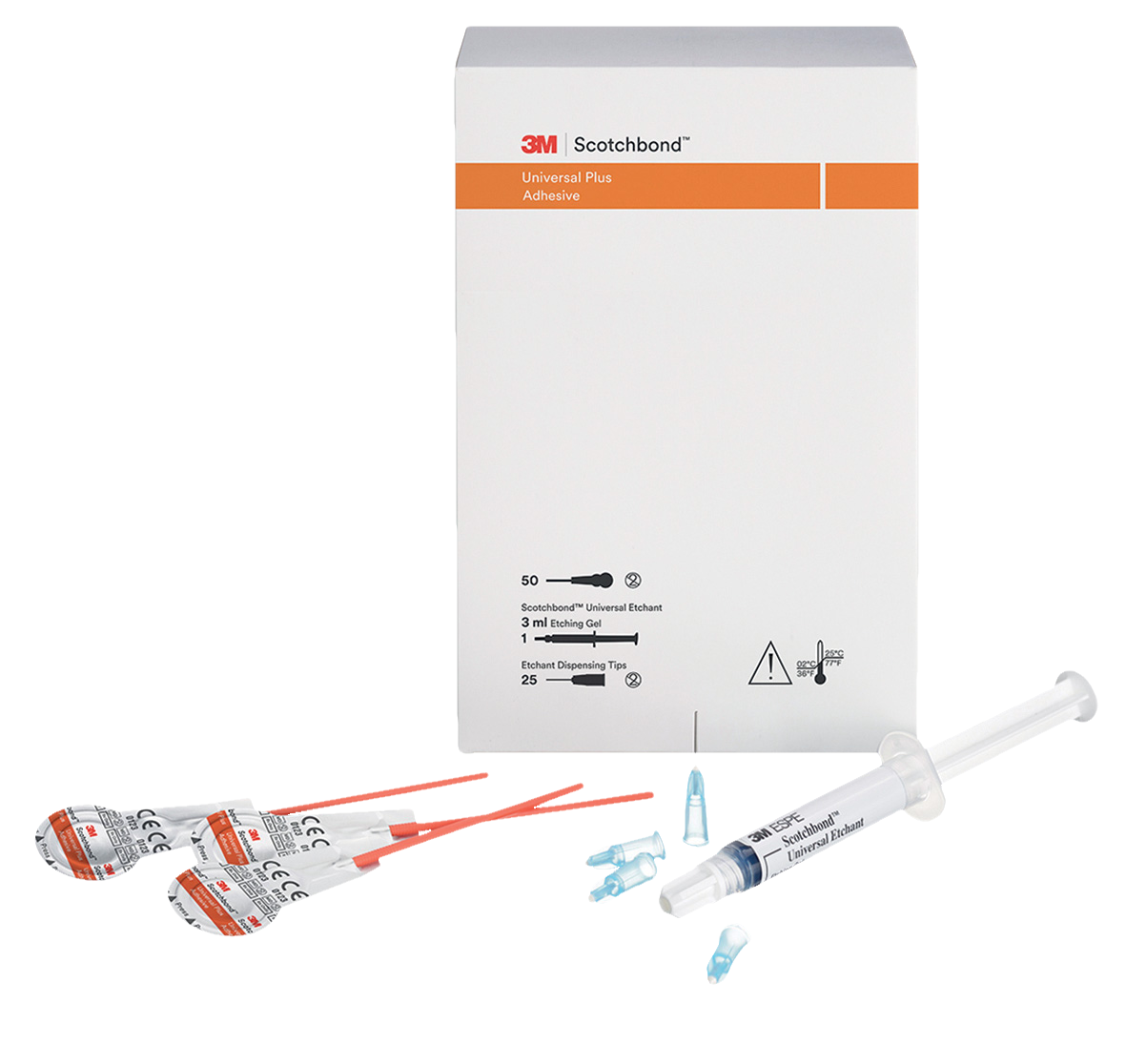

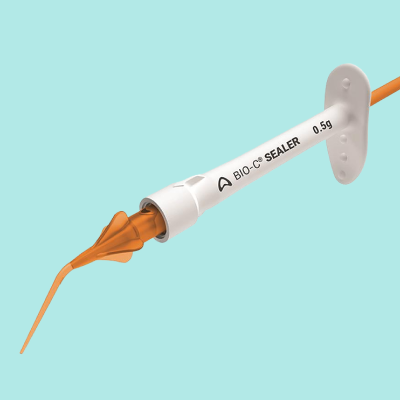

Cementation

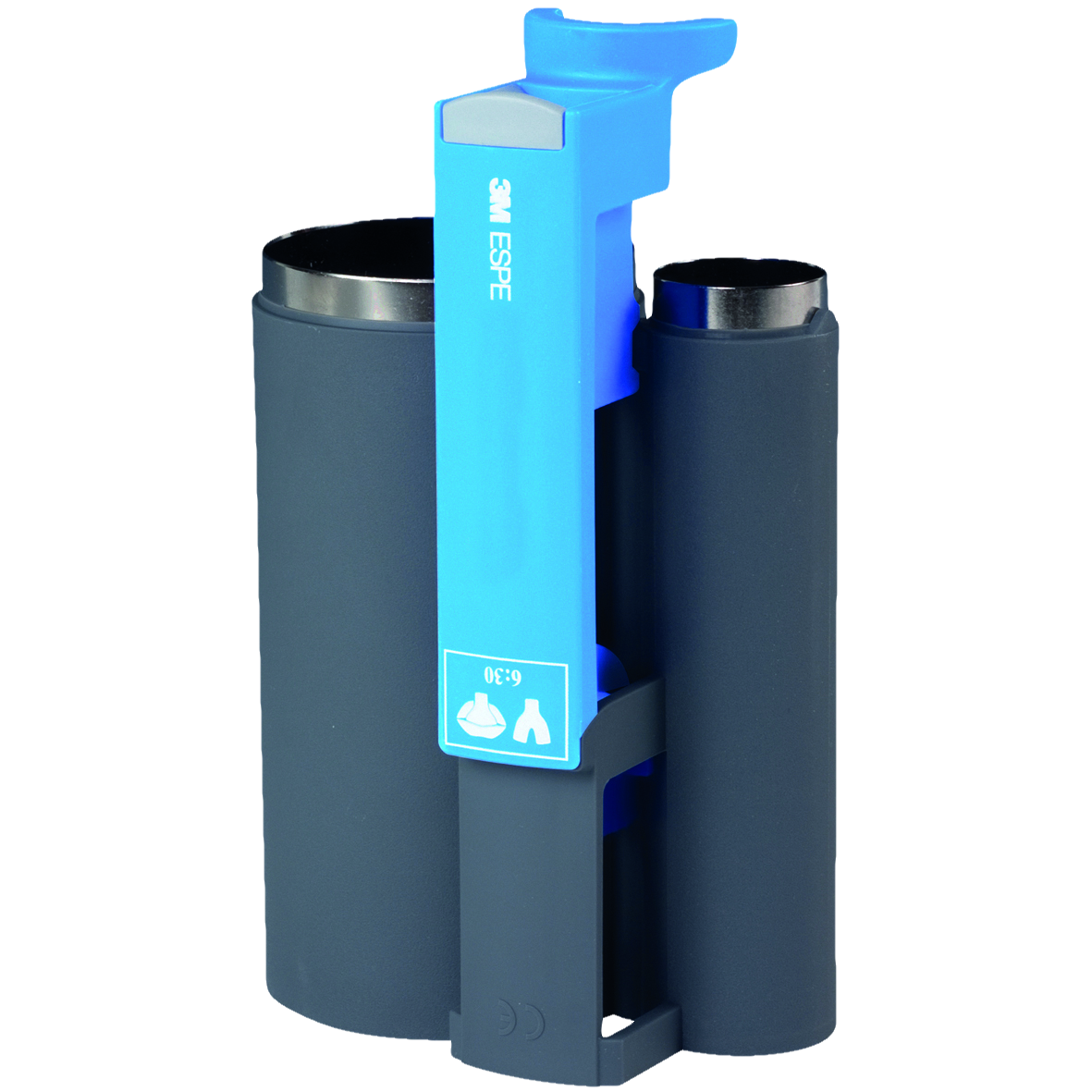

Luting cements have come along way and the most materials available today are delivered either in a capsule, which needs to be activated and mixed, or an automix syringe which allows a two component paste system to be extruded through a mixing tip to initiate the dual cure phase of the setting process. Cement mixing via an automix syringe has always been a challenge for product development teams.

The combination of mixing tip length, design of the internal tip spiral, the chemistry of the material and the timings of the dual cure activators are all key in making sure a dental cement works correctly and has the specified working and setting time to allow accurate seating of indirect restorations. The limitation is that the remaining volume of cement in the tip after dispensing is waste and must be disposed.

For the last few years, 3M has gone back to the drawing board and created a brand-new innovative tip that uses less plastic and reduces cement waste by up to 80% when compared to current automix delivery systems, without compromising performance and cement properties.

The new design allows for reduction in waste, less material needed per application, and a much smaller syringe system compared with other automix cements on the market. The smaller, more ergonomic syringe results in up to 50% less plastic waste compared to other automix syringes, but also reduces storage space.