Optimise Tooth Restorations With Voco's VisCalor and VisCalor Bulk

Two of the most popular dental materials from Voco GmbH, VisCalor and VisCalor Bulk are dental composites designed to optimise tooth restorations. Voco VisCalor is the world’s first universal composite to use thermoviscous technology.

What is Thermoviscous Technology?

Thermoviscous technology combines the advantages of a flowable composite and a sculptable composite in the one material. By pre-warming, the material becomes less viscous so can be placed in the cavity in flowable form. Within a few seconds the material quickly cools back down to body temperature and can immediately be sculpted just like a packable composite. Thermoviscous technology removes the need for multiple working steps for base filling or covering layers. It can also reduce the level of stock that needs keeping.

How is VisCalor Warmed?

Voco recommends warming its VisCalor capsules ready for application in one of two ways.

- The first method is with the use of a Voco Caps Warmer. This allows a short-term warming of up to 4 caps at the same time, which makes the device ideal for working with multiple shades.

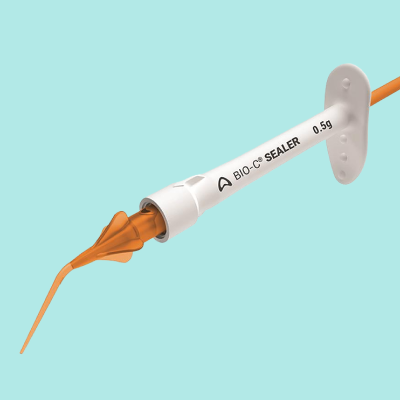

- The second method is with the VisCalor Dispenser. This warms up the capsules ready for them to be applied without the need to change devices. Warmed up rapidly using near-infrared technology, capsule temperature can be maintained for two and half minutes in the dispenser.

Both the Voco Caps Warmer and VisCalor Dispenser are available as individual units or as a set with VisCalor capsules.

What Shades Are Available?

VisCalor is available in three individual aesthetic shades (A1, A2 or A3) or as a universal composite that can be used across the entire classic shade range.

Universal shade composites are fast becoming a must-have for dentists as they can help prevent wastage and simplify the shade matching process.

VisCalor incorporates silica particles into a resin matrix that allows the material to reflect the colour of the adjacent tooth structure and blend to the surrounding teeth. This is commonly known as the chameleon effect.

Other benefits of a universal composite like VisCalor include eliminating shade matching for reduced chair time and avoiding the possible frustration of a colour shift after a composite has cured.

Other benefits of VisCalor and VisCalor Bulk

- Optimal flowing to margins and undercut regions to minimise the risk of marginal gaps

- Bubble-free application

- Excellent physical properties

- Slender cannula ideal for hard-to-reach areas

- Increment thickness of up to 2mm (VisCalor) and 4mm (VisCalor Bulk)

- No overlaying necessary

- Lower shrinkage after warming versus conventional bulk-fill composites (VisCalor Bulk)

VisCalor indications

VisCalor indications include

- Class I to V restorations

- Base fill (restoration base) in Class I and II cavities

- The reconstruction of anterior teeth damaged by trauma

An extensive list of clinical studies using VisCalor and VisCalor Bulk in a variety of indications can be found here: Clinical Cases

VisCalor Price

VisCalor Dispenser Preheating Device

VisCalor Dispenser Protective Foil 100pk

Capsule Warmer Accessory Tray

VisCalor Price

A simple definition of CAD/CAM dentistry is the use of digital software to design and manufacture dental restorations and prostheses. CAD stands for computer-aided design and CAM stands for computer-aided manufacturing. The technology can be used to create crowns, dentures, inlays, onlays, bridges and veneers among other things. The speed of the CAD/CAM process allows for dental prosthetics to be designed, manufactured and delivered to the patient in quick time, sometimes the same day. The wider system of using computer assisted technologies to produce restorations is known as CEREC (Chairside Economical Restoration of Aesthetic Ceramics).

VisCalor Dispenser Preheating Device

VisCalor Dispenser Protective Foil 100pk