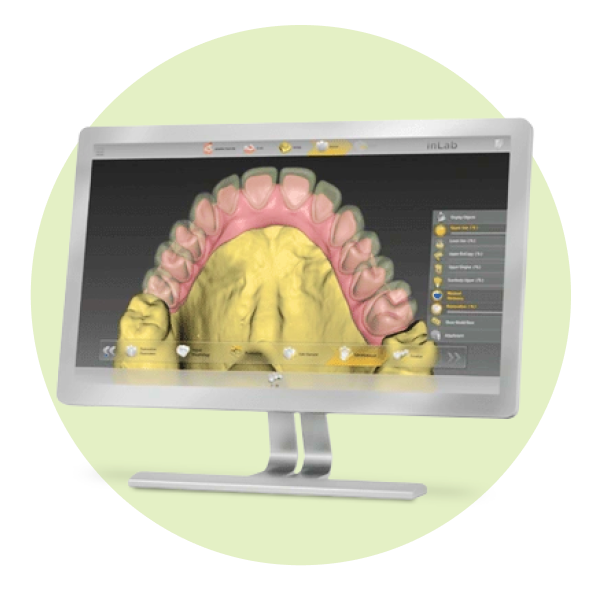

Though first used in some capacity as far back as the 1980s, it has only been in the last decade or so that its use has become commonplace thanks to major advances in the associated technology. Despite its potential to improve the design and creation of dental restorations, many dentists remain hesitant to adopt it. This guide aims to provide an overview of CAD/CAM, how it works, its core uses, advantages and disadvantages.

What is CAD/CAM Dentistry?

A simple definition of CAD/CAM dentistry is the use of digital software to design and manufacture dental restorations and prostheses. CAD stands for computer-aided design and CAM stands for computer-aided manufacturing.

The technology can be used to create crowns, dentures, inlays, onlays, bridges and veneers among other things. The speed of the CAD/CAM process allows for dental prosthetics to be designed, manufactured and delivered to the patient in quick time, sometimes the same day. The wider system of using computer assisted technologies to produce restorations is known as CEREC (Chairside Economical Restoration of Aesthetic Ceramics).

What is the CAD/CAM Process?

Once any necessary prep has been completed, an intraoral scanner is used to scan the necessary teeth and oral regions. The captured images are then imported onto a computer ready for the prosthetic to be designed. Designing can be done either chairside by the dentist or in a lab. Once designed, the digital impression is then transferred across to a milling machine which mills the final product out of a CAD/CAM block. The milled prosthetic is then stained and glazed to improve its appearance. Prior to this it may also need firing in a ceramic furnace for crystallisation and sintering, although some blocks such as GC LiSi Initial Blocks are fully crystallised to remove this step. Once inside the patient’s mouth, the prosthetic can be cemented or bonded into place, then adjusted as required.

What are CAD/CAM Blocks?

A CAD/CAM block is a solid block that is milled to produce a final or temporary restoration/prosthetic. CAD/CAM discs are also available in a circular shape.

The block is placed into a milling machine and cut to shape to match the imported digital design. This process can take anywhere between 10 and 25 minutes depending on the size of the design and speed of the milling machine.

CAD/CAM blocks come in various materials. These include zirconia, lithium silicate, ceramic and resin. Lithium silicate and zirconium ceramic blocks are the two most widely used materials.

- Lithium silicates, such as IPS e.max from Ivoclar Vivadent, are regarded for their high flexural strength, good aesthetics and ease of bonding. These blocks often come in a variety of shades and either high or low translucency.

- Zirconia blocks, such as ZirCad, are not as well regarded for their aesthetics but offer superior mechanical strength. This makes it a great choice for posterior restorations.

Both lithium silicate and zirconia CAD/CAM blocks are considered full-coverage blocks, meaning they are suitable for both anterior and posterior high-strength restorations.

What are the Advantages of Using CAD/CAM?

- Single visit treatments: The speed of CAD/CAM makes same-day delivery possible in cases where the dentist is comfortable and skilled enough to design and mill themselves.

- Patient comfort: Unlike with alginate and silicone impressions, there’s no goo, no gagging and no mess. Some scanners come with thinner tips for patients who cannot open their mouths wide.

- Advances in equipment: Scanners, milling machines and ceramic furnaces have come a long way in recent years, especially in terms of speed. Most scanners are now lightweight and easy to hold, with straightforward importing and exporting of files.

- Reduced shrinkage: CAD/CAM dentistry can reduce shrinkage in two different ways. The first is by designing and manufacturing a prosthetic greater than the required size. Doing this means that on firing it will only shrink to its originally intended size. The other way is by using CAD/CAM blocks that have already been fully sintered.

- Zero porosity: CAD/CAM blocks are made so that any internal porosities have been removed which is difficult to achieve during conventional impression fabrication.

- Lifelike results: CAD/CAM technology and blocks provide all the necessary tools and accessories required to produce lifelike restorations that fit well and are easily adjustable.

What are the Disadvantages of CAD/CAM?

- Learning curve: Understanding and getting used to a whole new technology can be challenging for dentists already short on time.

- Initial costs: CAD/CAM comes with some heavy upfront costs, including for the software, scanners and milling machine.