Dental handpieces are an essential part of any dentist’s armory and used daily for various procedures. Our guide to dental handpieces aims to provide a detailed breakdown of the different types of handpieces, their primary uses and key functionality to help you make an informed purchasing decision.

What Are The Different Types Of Dental Handpiece?

High speed turbines

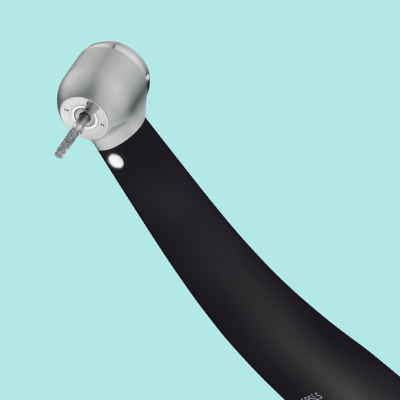

High speed turbines are one-piece units, meaning they are an entire system with an inbuilt motor. They can be connected directly onto the appropriate dental unit hose/tubing provided they are compatible.

These handpieces are slightly curved in appearance, with a head that can fit a variety of dental burs. More information on burs can be found in our Ultimate Guide to Dental Burs.

What exactly is a dental turbine and how does it work? Put simply, air pressure from the handpiece’s in-built air turbine is what drives the rotational motion of the bur for cutting or polishing. This is activated by the dentist stepping on the dental foot pedal.

Inside the head of the handpiece are lubricated ball-bearings which hold a friction-grip burr firmly and centrally, allowing the shank of the bur to rotate smoothly along a central axis with minimal friction.

High speed handpieces can reach speeds of up to 450,000 repetitions per minute (rpm).

The two small holes at the top of the handpiece head are where the air and water spray out from. The water coolant feature is used to prevent the tooth from overheating.

Low Speed Handpieces

Unlike single-unit high speed turbines, low speed handpieces are made up of more than one component. The low speed handpiece tubing on a dental chair requires the attachment of a motor which itself requires a straight handpiece, contra angle handpiece or prophy angle attachment. The motor that drives a low-speed handpiece can be either air or electric driven. Within the handpiece is internal gearings which allow the friction grip burr to rotate at a constant speed independent of torque.

As low speed handpieces are operated at lower rpms and remove tooth structure much slower, they do not require the addition of water spray, however some attachments do include this feature. Average speeds of a slow speed handpiece range from 10,000 to 40,000rpm. Rotation speed is determined by the motor operating it. Electric motors will typically rotate a bur at around twice the speed of an air motor.

Contra angle handpieces, which are curved in design, are typically used intraorally (inside the mouth). Straight handpieces are used more for extraoral (outside the mouth) procedures.

Electric Handpieces

Contra angles and straight angles can both be used as electric handpieces when connected to an electric driven motor. Electric handpieces are typically heavier and more expensive compared to air driven handpieces. However, they have several advantages and are generally considered superior in most departments, including power, control and torque.

Torque is the overall efficiency and cutting power of the handpiece. Though air driven turbines can reach up to double the speed of an electric handpiece, they lose about 40% of overall speed when cutting begins.

On the other hand, electric handpieces can maintain a constant speed and lose no power during operation. Torque settings can also be adjusted with electric handpieces to suit various procedures, including endodontic treatment. As they do not rely on air, speed increasing handpieces with electric motors also produce less aerosol than air turbines which is beneficial for infection control. Find out how here.

For additional help finding the right dental handpiece, motor, coupling or maintenance kit, speak to Jack our handpiece specialist on 01634 878759.

Talk to our Expert

For additional help finding the right dental handpiece, motor, coupling or maintenance kit, speak to Jack our handpiece specialist on 01634 878759.

Talk to our Expert

For additional help finding the right dental handpiece, motor, coupling or maintenance kit, speak to Jack our handpiece specialist on 01634 878759.

Handpiece Gear Ratios Explained

A handpiece’s gear ratio indicates its speed capabilities and what procedures the handpiece is most suitable to perform. Gear ratios can indicate if the handpiece is speed increasing (for example 1:5) or speed decreasing (for example 4:1).

A gear ratio of 1:5 offers higher speed and can be used for heavier duty procedures, such as cavity preparations and crown cutting.

A handpiece with a 1:1 ratio is low speed and will rotate a bur at a maximum of 40,000rpm (electric) or 20,000rpm (air driven). These handpieces have the same rpm as the motor.

Low speed handpieces are more suitable for lighter jobs such as refining a preparation, removing caries or adjusting ceramics.

Handpieces with a speed decreasing ratio of 4:1 will rotate four times slower than the driving motor.

Gear ratios are easily identifiable by their universal colour code (pictured). A red ring around the handpiece indicates speed increasing, a green ring indicates speed reducing and a blue ring indicates no change in speed.

Top Selling Contra Angles

A simple definition of CAD/CAM dentistry is the use of digital software to design and manufacture dental restorations and prostheses. CAD stands for computer-aided design and CAM stands for computer-aided manufacturing. The technology can be used to create crowns, dentures, inlays, onlays, bridges and veneers among other things. The speed of the CAD/CAM process allows for dental prosthetics to be designed, manufactured and delivered to the patient in quick time, sometimes the same day. The wider system of using computer assisted technologies to produce restorations is known as CEREC (Chairside Economical Restoration of Aesthetic Ceramics).

Concentricity

Electric handpieces are considered to have greater concentricity compared to air driven handpieces as the turbine is more likely to experience concentricity-compromising wear and tear.

Illumination

Emitted from the handpiece head, in-built fibre optic lighting can be used to illuminate the cutting surface and assist with intra-operative vision. Further detail on fibre optics can be found here.

Noise

To protect against this, handpieces should ideally produce as low a decibel (dB) rating as possible without compromising performance.

Air driven turbines generally produce more noise than electric handpieces.

Patients may find quieter handpieces easier to tolerate, however some dentists use the sound created by the handpiece as a guide, so it’s important to weigh up these factors

Head size

Large heads (14.5 x 13mm) produce more torque and cutting power which speeds up procedures.

Standard sized head sizes (11.9 x 10.2mm) are considered a middle ground that can offer the partial strengths of both with no glaring weakness.

Grips

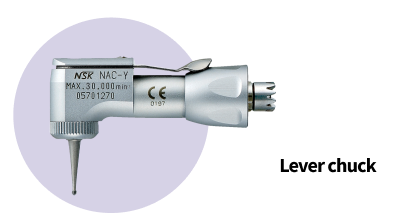

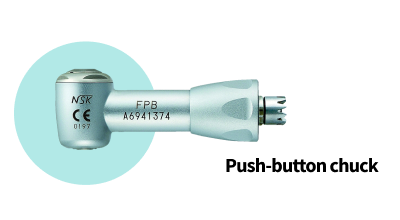

One of the most basic decisions a dentist must make when choosing a handpiece is what type of chucking mechanism to use (i.e. how is the bur retained and changed?)

Autochucks are by far the more popular choice as they do not require the use of any other tools to open or close the chuck. Located on the back of the handpiece head, autochucks can release a bur or lock it into place using either a push-button or lever system.

Manual chucks are considered somewhat outdated and involve the use of a small wrench to secure and loosen the bur.

Bearings

Whatever material is used, it is crucial to keep bearings in the best condition by cleaning and lubricating them often in accordance with the manufacturer’s instructions.

Ergonomics

The lighter the handpiece, the more comfortable it should feel to use. Modern handpieces are designed to be lightweight and perfectly balanced - ideal for using for extended periods of time without causing strain.

Some handpieces, such as the BA250LT and BA200LTS contra angles, come with a PVD "smart coating" for enhanced grip.

Handpiece manufacturers

Ensure you always buy your handpieces from a reputable dental supplier such as Kent Express. Don’t be tempted to buy cheap copies online, for example from well-known auction websites – you have no idea where the product is manufactured, quality is often an issue, and cheap copy handpieces often do not meet European safety standards.

Ensure your handpiece holds the CE mark and look for manufacturer guarantees. Ensure the manufacturer can offer technical support post-purchase if required.

The country of manufacture is also important: Germany, Austria, Switzerland and Japan are known to produce excellent quality handpieces.

Handpiece Repair

However well you maintain your dental handpiece, there’s bound to come a time when it needs repairing. Always consider repairing your handpiece first before purchasing a brand new one.

Signs that your handpiece may need repairing include if it is emitting excessive vibrations, if it is not rotating as fast as it should or it’s making unusual noises. If these issues occur, it is worth having your handpiece checked over as the inner mechanisms might need a professional repair.

Handpiece and Equipment Repairs

In partnership with B.A. International, Kent Express provide a fast handpiece and small equipment repair service.