Reasons to Switch to an Electric Contra Angle

With infection control as important now than ever before, any adjustments or upgrades that can reduce the risk of virus particle transmission should be strongly considered. While surgical masks are essential, they do not offer complete protection from aerosol splatter so should be supported by the right handpieces and equipment for extra precaution. Making a switch to electric contra angle handpieces is a great place to start given they generate fewer aerosols than high-speed turbines as a result of being operated at 200,000 rpm, which is around half the speed. The intensity of particle distributed is reduced. This helps to limit the water spray generated.

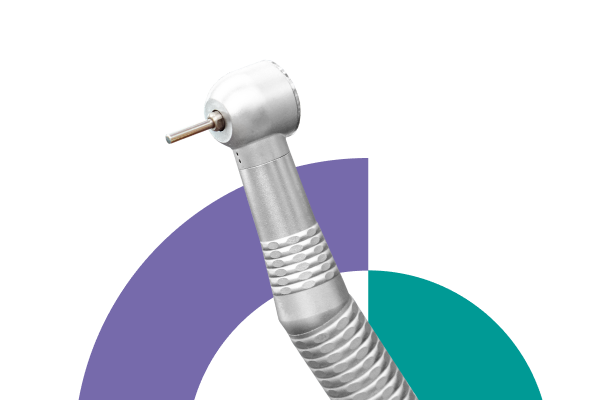

What is a Contra Angle Handpiece?

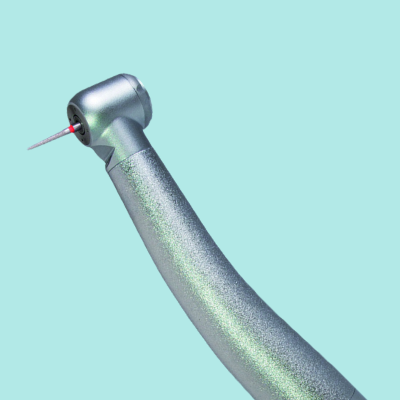

A contra angle handpiece is a dental instrument built with an angled shaft to reach less accessible areas of the mouth. Typical dental work that involves the use of a contra-angle includes endodontics and implantology procedures, such as removal of caries and refining a cavity preparation.

The best contra angle handpieces will be speed increasing, meaning they can easily switch from low speed to higher speeds.

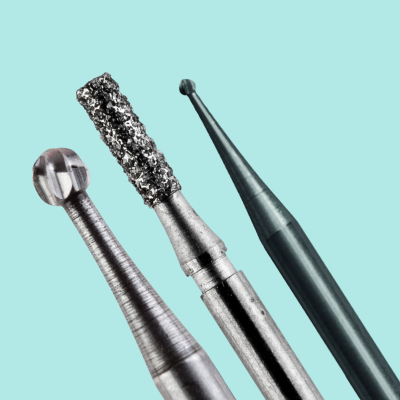

A dental bur is placed at the end of the contra angle handpiece depending on the need for each situation.

What is the Benefit of Electric Contra Angle Handpieces?

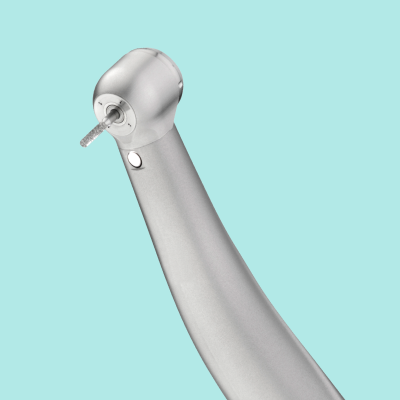

In addition to aiding infection control through generating less aerosol, the most efficient electric contra angles, such as the BA250LT, offer the following benefits:

- Higher efficiency at cutting various materials due to the much higher and consistent torque vs turbines

- Quieter operating noise - more comfortable for patients

- Retractable light guide that allows fitting to both optic and non-optic motors

- Ergonomic design for a better grip

Electric contra angle handpieces work by connecting to your inbuilt dentist chair motor or an electric micromotor.

What is an Electric Micromotor?

For chairs that do not have inbuilt motors, an electric micromotor is required to power the contra angle or straight handpiece. Electric micromotors are simple to set up and do not typically require a technician. Just simply plug in and play, and you’re all set. As well as easy installation, modern electric micromotors will be compact and lightweight in design, and feature an internal spray and LED light, a flexible speed range and brushless motor technology for a longer life cycle.

The Ultimate EM420 Micromotor from BA has all the above features, along with two programmable memory functions.

Matching your contra angle handpiece and micromotor

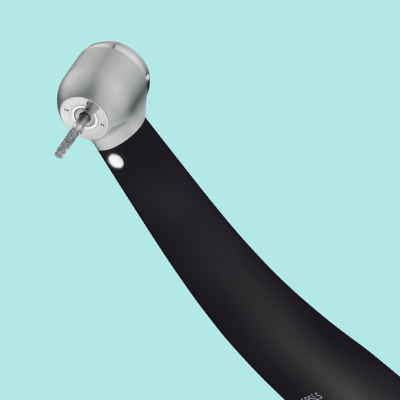

BA Ultimate 1:5 C/A Quadruple Spray F/O BA250LT

BA Ultimate Micromotor EM420

Matching your contra angle handpiece and micromotor

A simple definition of CAD/CAM dentistry is the use of digital software to design and manufacture dental restorations and prostheses. CAD stands for computer-aided design and CAM stands for computer-aided manufacturing. The technology can be used to create crowns, dentures, inlays, onlays, bridges and veneers among other things. The speed of the CAD/CAM process allows for dental prosthetics to be designed, manufactured and delivered to the patient in quick time, sometimes the same day. The wider system of using computer assisted technologies to produce restorations is known as CEREC (Chairside Economical Restoration of Aesthetic Ceramics).

BA Ultimate 1:5 C/A Quadruple Spray F/O BA250LT